Whatever metal packaging you manufacture, it all starts with large steel coils delivered to the manufacturing plant. These are then cut into sheets, varnished, and in some cases, printed. The varnish helps protect against corrosion or possible interaction with the packaged product. Each packaging is checked during the various stages of its manufacture.

The metal sheets thus prepared are cut into strips and sides, then transformed into a cylinder and welded or stapled.

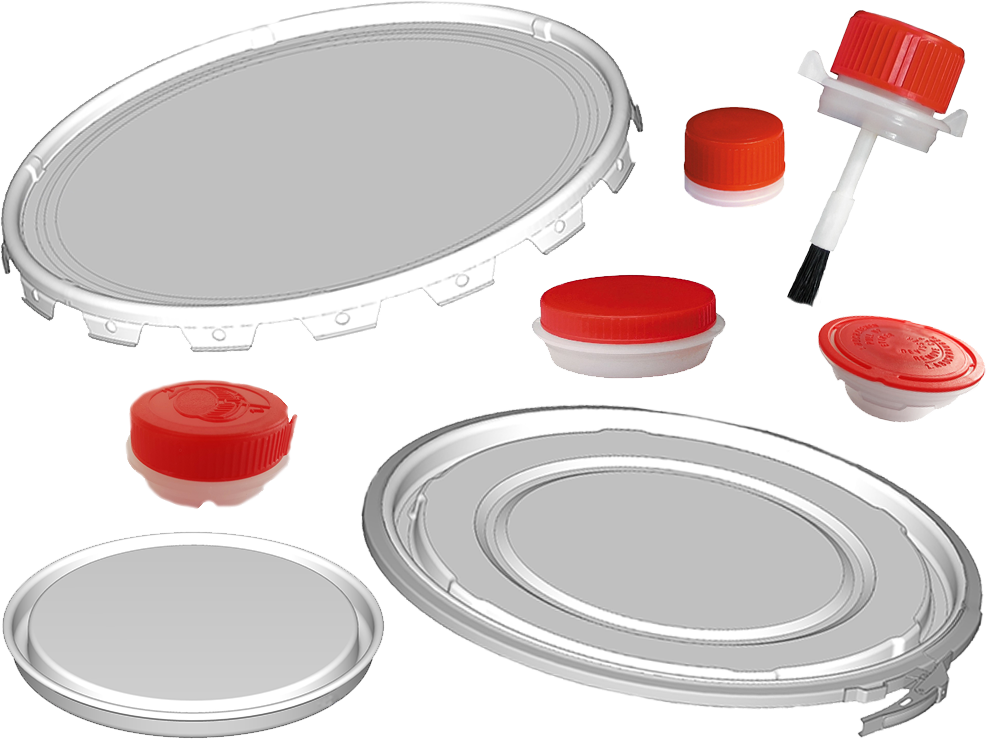

This cylinder will remain a straight cylinder or will take, thanks to the expanders, a conical, rectangular, square or hexagonal shape. Depending on the desired packaging (box, can, bucket or tray), the crimping of the accessories (bottom, ring, pierced top, etc.) is the last step in the assembly process.

A total opening will be closed by a cover or a stopper.

A partial opening will be closed by a neck whose diameter varies according to the customer's wishes or technical constraints. The boxes and lids are then sent to the end customer for packaging and closing the packaging by capping, crimping or capping.

Once thrown in the sorting bin, the metal packaging goes to a sorting center where it is isolated from other packaging waste using a magnet. The steel packaging is sent to the steelworks. They are then placed in the oven, then rolled to be transformed into coils, bars or wires depending on the use (household appliances, construction, automobile, packaging).

In addition, incinerated household waste may contain metal packaging which unfortunately has not been captured / sorted upstream. On leaving the incinerator, the non-combustible materials are recovered in the form of bottom ash.